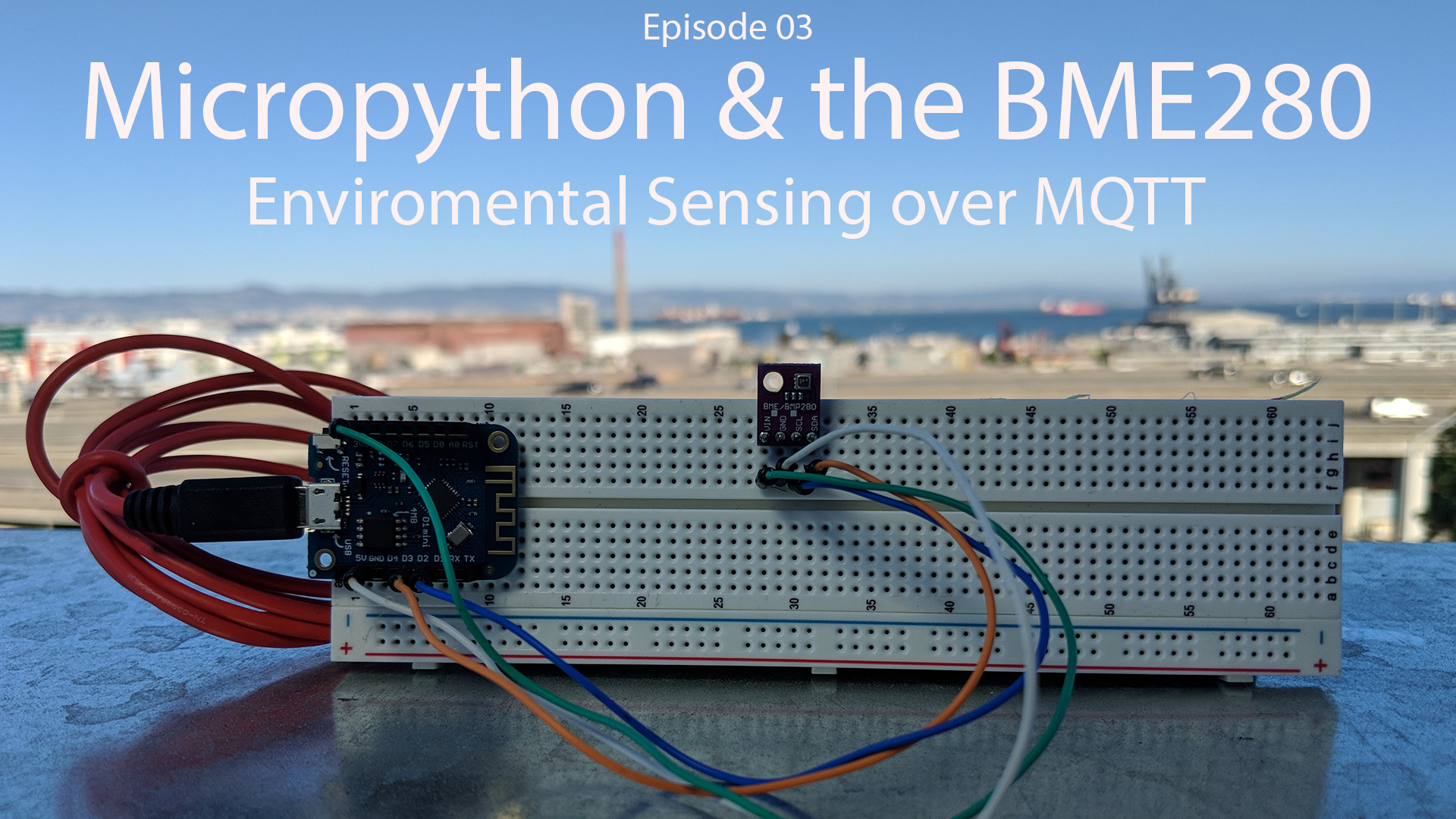

Video Tutorial: BME820 Environmental Sensor and MQTT under Micropython

This week we’re starting to make our Micropython powered Wemos D1 truly useful with a sensor and data collection. We’ll wire up a BME280 sensor which measures temperature, humidity and air pressure. After we know it works, we’ll use Wifi and MQTT to send the data to a website for viewing.